Italferr designs and builds depots and workshops for rolling stock in Italy and abroad.

Italferr designs and builds depots and workshops for rolling stock in Italy and abroad.

Dynamic Multipurpose Facility (Impianto Dinamico Polifunzionale)

Italferr contributed to the construction of the Dynamic Multifunctional Facility (IDP) of Naples, the new maintenance center for the entire fleet of HS trains and rolling stock destined for regional transport.

Activation of the IDP took place in phases: in 2002, the arrivals and departures bundle consisting of six covered tracks and six uncovered tracks dedicated to current maintenance and cleaning of Eurostar trains was activated.

In a second phase, the Central Computerised Interlocking (ACC) was activated to regulate the circulation between Napoli Centrale and the arrivals and departures bundle, whose Interlocking's conformity certification was entrusted to a technical verification commission consisting entirely of Italferr experts.

In the third phase, "distributed logic" safety equipment was activated in anticipation of realising the completion of the system itself through a "concentrated logic" ACC.

In 2008, the entire ACC system was activated and the mechanical systems governing the yard were completed.

Cyclical Maintenance Workshop (Officina di Manutenzione Ciclica)

Detailed and executive design and execution of works to upgrade the HS Fleet Maintenance workshop.

The Vicenza workshop, built in the early 1900s and upgraded in various stages over the following years, occupies an area of about 140,000 m2 in the city's industrial area, located adjacent to the Milan-Venice railway line. In recent years, the increase in the number of HS trains in the fleet has made the Vicenza OMC a strategic hub for the maintenance of new trains, particularly for ETR 500s and ETR 1000s, which has required upgrading and retrofitting of the workshop itself to ensure the new procedures.

Current Maintenance Facility (Impianto di Manutenzione Corrente)

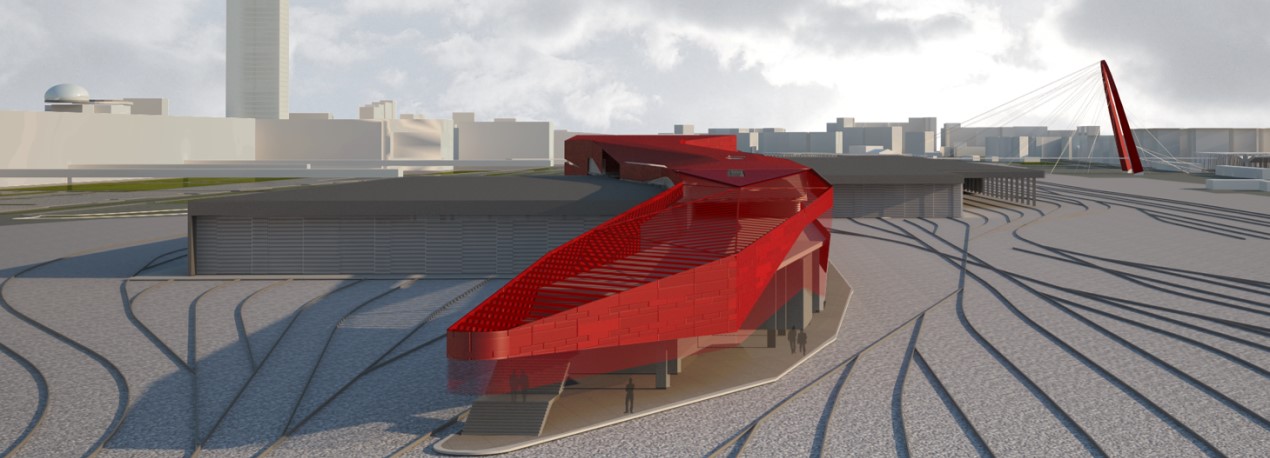

Executive design and execution of the works of the new Trenitalia IMC. The interventions allow for a reorganisation of the rail layout plan and the construction of new buildings of modern conception, where all maintenance operations will be centralised, for performing with maximum efficiency and respect for the environment the maintenance of regional transport trains and HS service.

The area targeted by the interventions covers about 270,000 m², within the yard of about 340,000 m² where Trenitalia currently carries out maintenance activities. The project aims to insert a production infrastructure/facility in an area where major urban regeneration interventions have been implemented by the municipal administration through the construction of sports facilities, offices, commercial and residential complexes. Starting from the aforementioned context and considering the expectations of the city of Turin, the project aims to give a unified design to the new facility, by formally and functionally harmonising the new architecture, the infrastructure and the pre-existing urban assets.

Current Maintenance Facility (Impianto di Manutenzione Corrente)

Executive Design and Works Supervision of the interventions necessary for the construction of a new shed dedicated to the maintenance of ETR 1000 trains in the new IMC HS facility. In particular, a new shed named "MAV3" has been built with the consequent adjustment of the access tracks to it on the Milano Centrale side and on the Milano Greco Pirelli side, as well as of the road system inside the facility with the construction of service roads, paved areas and parking lots.

The newly built shed has internal floor dimensions of approximately 340 x 25 m with an average net height of 9 m. The elevated part of the building was substantially built by using prefabricated reinforced concrete structural elements and the three tracks inside the shed were laid on prefabricated inspection pits.

Adjacent to the main building is the Auxiliary Services Building intended for offices and locker rooms for personnel engaged within the facility about 100 m long and about 7 m wide, arranged on two floors.

The facades of the new architectural complex have been finished with the use of composite cladding panels and corrugated sheets; the longitudinal elevations feature the presence of elements delineating a tricolour band.

The new ETR1000 shed is equipped with a state-of-the-art tooling system for rolling stock maintenance.

Current Maintenance Facility (Impianto di Manutenzione Corrente)

Executive Design and Works Supervision of the interventions necessary for the construction of a new shed dedicated to the maintenance of ETR 1000 trains in the new IMC HS facility. In particular, a new Shed named "MAV3" was built with the consequent adaptation of the access roots to the same on the Milan side. Construction of new buildings and upgrading of existing ones, complete with all the necessary equipment and interventions to the superstructure, electric traction and signalling systems within the Trenitalia facility.

The upgrading of the IMC in central Bologna is the first Executive Project of a maintenance facility developed by Italferr directly with BIM methodology in order to allow the client a future use of the BIM models for the management and maintenance of the buildings.

Execution of works and supplies for the reconversion of several industrial buildings for office use and operating facilities related to railway activities.

The project is part of the broader redevelopment of the Florence Railway Hub, which, following the entry into operation of the Osmannoro Railway Hub, sees large building volumes in the area of the Romito locomotive depot made available by the divestment of former maintenance activities. The recovery of the former engine shops of Firenze Romito is the first Executive Project of a building developed by Italferr directly with BIM methodology in order to allow the client a future use of the BIM models for the management and maintenance of the buildings.